Thomas 隔膜技术的优势

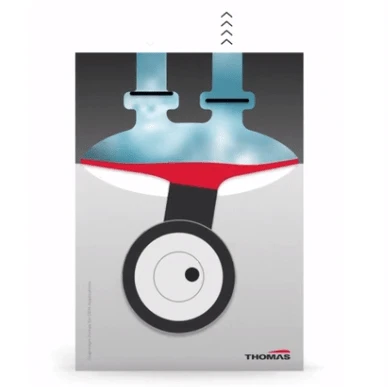

我们先进的工程和设计保证了气密性和可靠性。根据对被输送介质的耐化学腐蚀性,我们有各种泵头和隔膜材料可供选择。客户可以根据所选机型,从 EPDM、FKM(氟橡胶)、硅胶、NBR (Perbunan)、PTFE(聚四氟乙烯)中选择隔膜和阀门材料。

Thomas 隔膜技术特点

我们有各种交流和直流电机来驱动装置,其中包括低成本直流电机、无刷直流电机等等。隔膜泵的泵头可以使用单电机、双电机或 Z 型电机。我们的隔膜装置可采用串联或并联配置。此外,设备更小型,一台 Thomas 泵装置可代替多个泵。

Thomas 隔膜气体泵、真空泵和压缩机的流量范围为 0.010 立方英尺/分钟(300 毫升)至 3.2 立方英尺/分钟(91 升/分钟),真空度为 1 毫巴(绝对压力)(29.2 英寸汞柱),压力高达 3.0 巴 (44 psi)。

值得信赖的合作伙伴,可满足不同的 OEM 需求

我们的工程师会加倍努力,满足极其严格的应用和项目要求。一体不能万用。于是 Thomas 隔膜泵推出可广泛定制的平台,根据不同的型号系列,给您带来无限的配置选择。

我们由此得以提供市面上种类丰富的隔膜气体泵、真空泵和压缩机。我们的 27 个产品系列结合不同配置,有 100,000 多款装置供选择。

面向各种 OEM 应用的隔膜泵和压缩机

隔膜泵和压缩机效率高,有气密室、噪音水平低,是各种行业和应用的理想选择。在需要高效、紧凑型真空泵或压缩机的各种应用领域,都有成功运用此类产品的记录。使用我们的无刷直流驱动型泵和压缩机的任务关键型和便携式设备可运行 10.000+ 多个小时,我们深以为豪。

使用隔膜泵和压缩机的特色应用

- 医疗和实验室仪器

- 医疗和牙科高压灭菌器

- 负压创伤治疗技术 (NPWT)

- 二氧化碳检测仪

- 手持式或便携式气体检测仪和分析仪

- 汽车尾气分析