Thomas 蠕动泵的优势

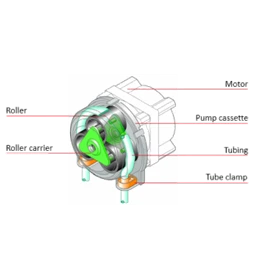

Thomas 拥有自吸、干式运行蠕动泵技术,其设计简化了维护,注重易用性。蠕动泵是泵送剪切敏感性物质的理想解决方案,该项泵技术能够轻柔平稳地移动液体。

我们的泵产品的流量范围从小于 0.1 毫升/分钟到高达 3000 毫升/分钟。特殊型号可以处理高达 10 巴的高压。

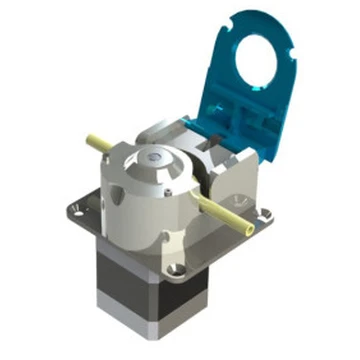

我们的管式泵由交流、直流和步进电机驱动,可顺时针或逆时针运行。此外,泵系统可以进行短时或连续运行。因而,每个原始设备制造商都可以根据自己的应用找到合适的产品。

一款适合各种应用的理想蠕动泵

人们常说的管式泵有一个巨大的优势: 在无交叉污染风险的情况下,准确配量或计量。凭借这一优势,蠕动泵成为各种行业和应用的理想选择。

例如,在医疗或实验室设备中,蠕动泵可用于处理无菌液体、透析、过滤或生物处理。食品、农业或消毒工艺可以用它们来分配食品或饮料、维生素或化学品。也可用于废水处理或其他环保应用,如气体分析中的冷凝水排出。

使用蠕动泵的特色应用

主要的医疗应用:

- 透析

- 医疗设备

- 清洗机/高压灭菌器

- 配量应用

主要的工业应用:

- 冷凝水排出

- 工业洗碗

根据您的需求量身定制

Thomas 工程师可以通过改造泵头部件、电机和管子来定制软管泵,满足您的具体要求。Thomas 根据您的需求,提供适合各种流体的不同管材。

- 标准 Novoprene 管,适合各种应用,寿命长。

- Norprene® 管,适用于碱性液体,寿命同样很长。

- PharMed BPT®,一种高品质管,专门用于医疗、实验室和研究领域。具有独特的结构,保证了耐化学品腐蚀性的提高。寿命长、具有生物相容性,适合高压灭菌器。

- 硅胶管,可以在较宽的温度范围内保持弹性,是极性溶剂的理想选择。